In my first article for fiberglass designs for Animal Scene’s January 2016 issue, I shared how I used my corporate knowledge as a fiberglass consultant to develop ponds, tanks, and filters for fish. My main aspiration was to produce these items with as many benefits as it could provide. I wanted these pet items to be like musical instruments or home furniture that would last a lifetime and become a part of my life.

As I browsed the internet and attended both local and international pet shows, the number of new designs for tropical fish products fascinated me. Most, if not all, available commercial items did not possess the major features that made up my wish list. This inspired me to add more functionality to my ideas using the simplest design.

In my previous article on the basics of design to actual creation, I shared three major processes in creating a product:

- Idea – What is the desired result? I list down what needed improvement and start sketching initial designs.

- Designing – With the help of my graphics team and using software for sketching and rendering, we include specific measurements. We render it for reference, which makes it look more realistic.

- Fabrication – My technical team provides me with the blueprint design in full detail.

Using the above processes, let us look at modern ponds as a sample project.

Level Up

With previous success in manufacturing a classic pond, I wanted to challenge myself more by designing ponds for homes that had space limitations, such as townhouses and condominiums. I wanted it to have a plug-and-play function wherein anyone could use it as it was or add on cladding to give the desired aesthetics. The range of versatility would be wide since it could be used indoors and outdoors.

My friends could not believe that I had that goal without intending to profit from it. I wanted a purely creative challenge.

Eventually, I called them Fiberglass-Reinforced Plastic (FRP) modern ponds.

Shape and Function

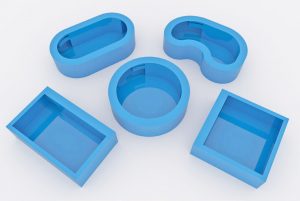

My ideas for shapes were inspired by European, Asian, and contemporary themes.

Kidney and guitar shapes worked best for small gardens. They would do well if submerged below-ground for top viewing. Nice fish to add in would be goldfish, red platys, red swordtails, and yellow and marble mollies. Interestingly, garra rufa or Dr. Fish could be wonderful add-ons that allow for plenty of interaction for the hobbyist. It would also be lovely to set up red ear turtles with these ponds.

Round and oval shapes would be ideal for top-ground locations. The hobbyist could make wood cladding for a zen effect or clad bricks for a water well effect. Ideal inhabitants include goldfish and red swordtails.

L-shape and square ponds could work well submerged or on the ground for minimalist or zen motifs. They would make very lovely indoor ponds, especially with accent pebbles and rocks surrounding them. Same as with the round ponds, goldfish and red swordtails would be good fish to keep.

Step ponds are suited for the hobbyist with a wide imagination, especially if they had ideas of extending the hobby. They could have a two-in-one function, providing a view from the top like a pond, and also at the front just like aquariums.

Grow out ponds. Each layer from the top would increase its volume of water. For grow-out purposes, the breeder could do the sizing of fry every week.

Multiple fish variety. As long as the water requirements remained the same, the hobbyist could take care of three kinds of fish, such as cichlids, livebearers, tetras, danios, and barbs.

Fish gallery. This could display fishes with different colors or strains to highlight their beauty, including goldfish, angelfish, guppies, and even corydoras.

Asking the right questions

When I talk about fiberglass, I always end by cautioning hobbyists when buying commercially-available FRP products. One should ask these questions:

- Is the product made of pure fiberglass?

- Is the manufacturer knowledgeable in the types of raw materials used in making fiberglass?

- Does the manufacturer give a warranty?

- Does the manufacturer know how to fabricate using the right methods?

- Does the manufacturer offer after-sales services?

Conventional ponds use cement, hollow blocks, and a membrane-type waterproofing coat. The filtration piping is embedded at the bottom of the pond. For small and medium ponds, the most common filtration used is the commercially-available closed system type. This type is usually made of plastic and has several compartments for mechanical, biological, and chemical functions.A common mistake for small pond owners includes putting small kois in, which will eventually almost outsize the pond.

A downside of small ponds is that water parameters are harder to maintain, but the cost maintenance compensates for this difficulty. They are also safer for kids and senior citizens. As modern fiberglass ponds offer the same functionality as aquarium tanks, I hope that they provide more options for people to discover the journey of fishkeeping.

This appeared in Animal Scene magazine’s June 2018 issue.