Fins, Feathers, Fur, Fiberglass

I was in grade two when my uncle Teodoro Sun gave me my first set of black mollies, which I placed in plastic jars. This marked the beginning of my passion for pets. I eventually upgraded from a 2.5 gallon galvanized framed aquarium to one which was all glass.

Thereafter, dogs, racing, and fancy pigeons, finches, and African lovebirds caught my fancy.

After graduation, I got involved in the fiberglass industry. Here I was able to formulate, design, and fabricate industrial products. I worked with international companies, which enhanced my knowledge. I was able to learn different applications for specific needs. This gave me the idea of coming up with products for my pets. I made an inventory of items and equipment which I used for my pets and realized that there was so much room for innovation. Again, this made me apply my job knowledge to my pets.

At this point, I would like to share some information on fiberglass. Fiberglass or FRP (Fiber reinforced plastics) technology has been in use for decades. They are use by first world countries. Third world countries do not utilize FRP technology, for the most part, because of reasons such as price compared to the value of use, and lack of knowledge of making quality FRP products.

Long-range applications for FRP include:

- Handicraft industry: figurines and furniture

- Industrial factory: tanks, pipes cooling towers

- Construction materials: roofing, cladding, p-traps, counter tops

- Transportation: boats, electric cars, trains

The major reasons I decided to create products using FRP for my pets:

- Durability compared to those commercially available in the market

- Appreciation of value• Flexibility of design

- Allows me to explore my ideas

How I do it:

Idea: What is the desired result? I will list down what I want to improve and start sketching my initial designs.

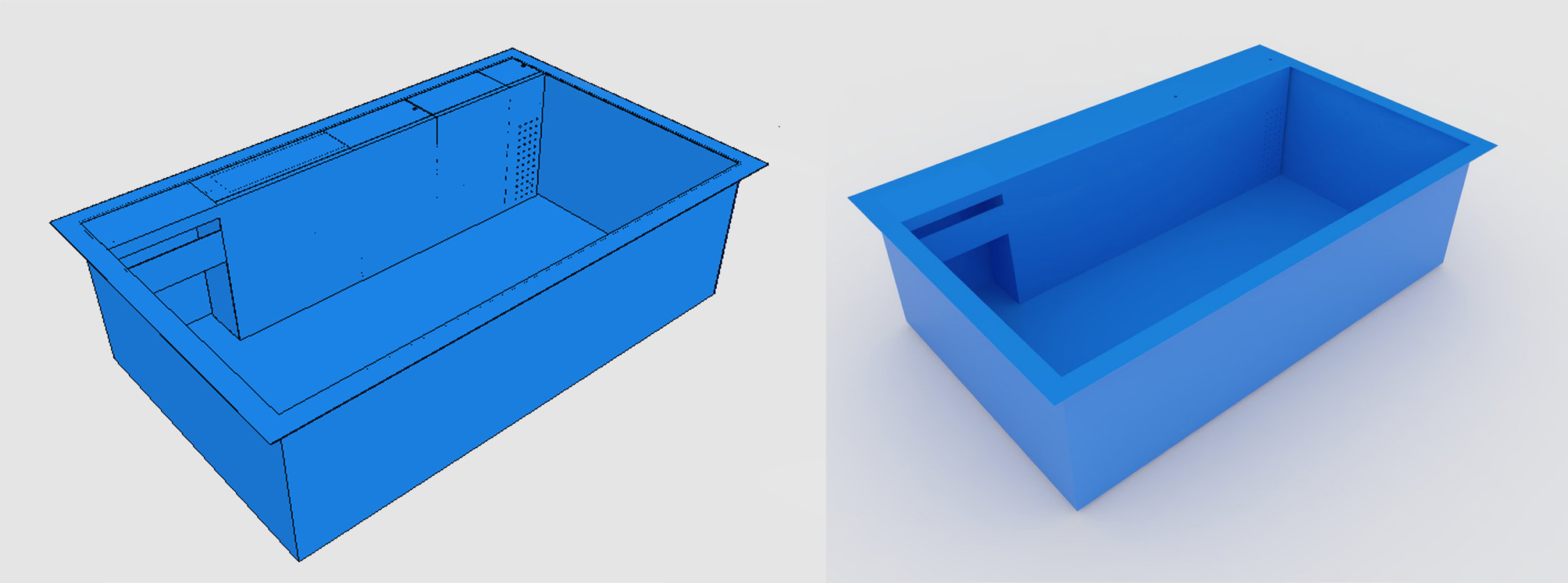

Designing: With the help of my graphics team, using software for sketching and rendering, we will include specific measurements. We will render it for reference, which is more realistic.

Fabrication: My technical team will provide me with the blueprint design in full detail.

•Rendering – Figure 2 Right (Using rendering software for realism)

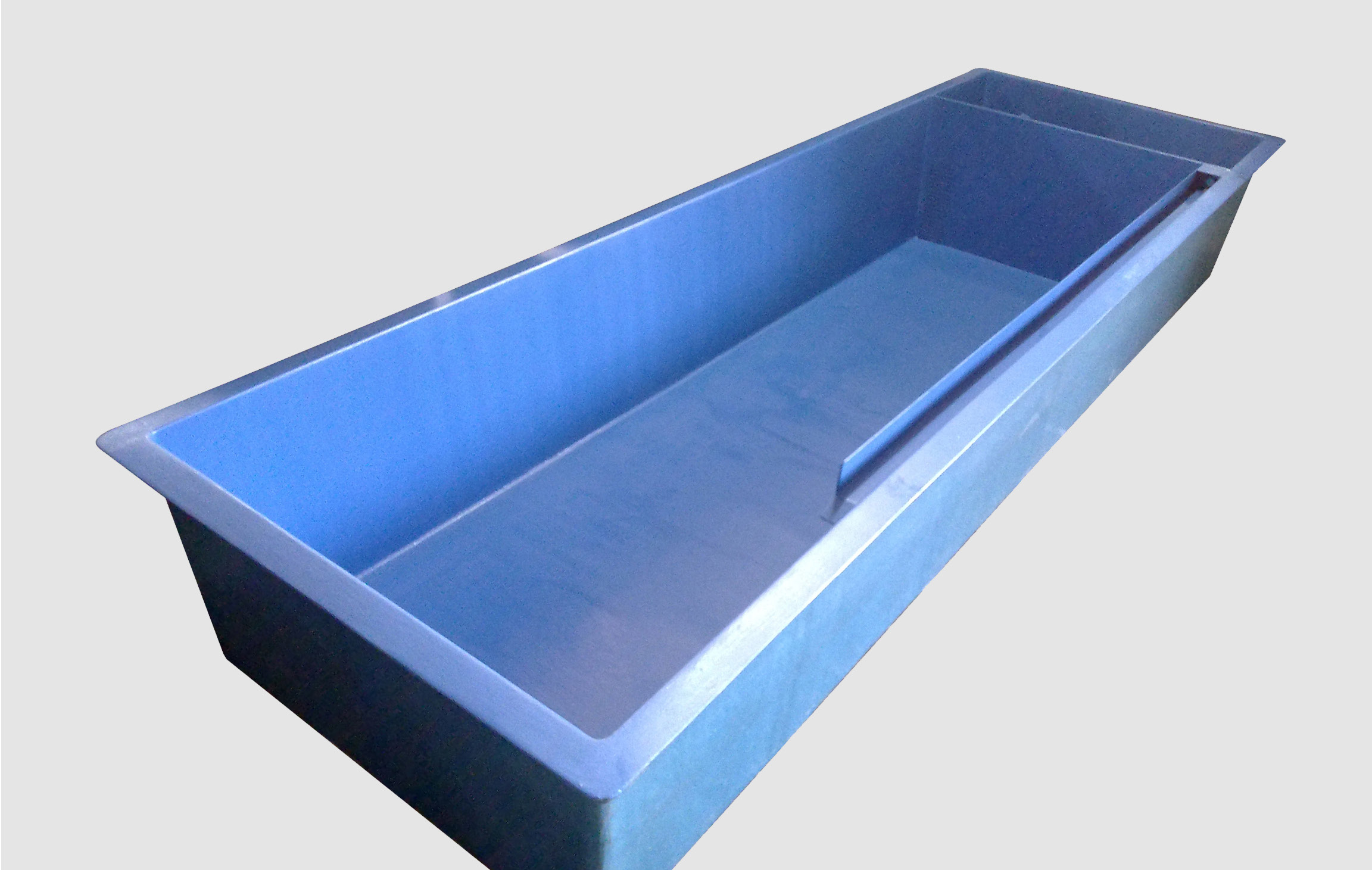

Sample project: Standard pond

- Idea: Desired results

Ø Create a plug and play pond

Ø Waterproof

Ø Will last 10 years or more

Ø Can be used below, between, and above ground level

Ø Built-in filtration system, including mechanical, biological, and UV lights.

Ø Rain effect of the outgoing water

Ø Movable

Ø Produces clean water and algae growth on the side and floor surface

Most of my standard ponds give more than 10 years of service. I will be sharing more of my projects.

Word of caution for those buying commercially available FRP products—check on the following:

- Are they pure fibreglass?

- Is the manufacturer knowledgeable on what kind of fibreglass raw materials to use?

- Do they give warranty?

- Do they know how to fabricate using the right methods?

- Do they have after sales service?

Let us all remember that there is a big difference between price and value. I want to quote a previous column in Animal Scene written by my very good friend Johnny Filart regarding buying equipment for our beloved pets: “Expensive is cheap.” I could not agree more.

This appeared in Animal Scene’s January 2016 issue.